- Turnkey product design, development, simulation and prototyping

- In all areas of Tooling design, manufacturing and supply,

- Design and Optimization of Processes, Tools and Plant Layouts

- Process & Robotic simulation

- As your turnkey solution provider, we can design, develop, deploy, commission, train, and support start of production to implement your manufacturing line.

- Redeployment / Transfer of Vehicle Manufacturing

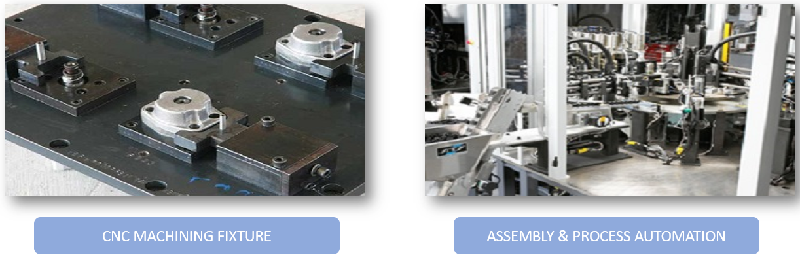

- Design and manufacture of SPM’s for assembly and process automation

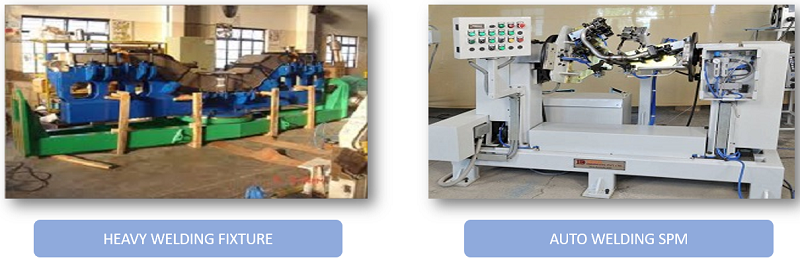

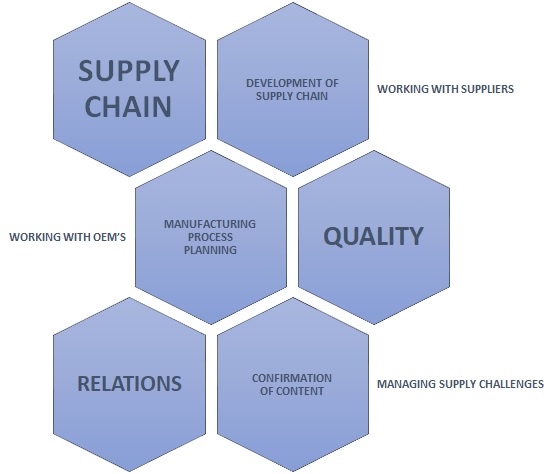

We provide anywhere from updated toolkits to modify and enhance your current tools to providing a complete turnkey solution for your manufacturing plant. We are capable of processing, design, development, fabrication of the tools, CMM, tryouts, commissioning, support start of production. We also provide and support CMM reports, and PPAP. Checking fixtures, in-plant conveyance, and dunnage are part of our turnkey solutions.

Fully automatic, Semi-automatic, and Manual weld lines for:

|

|

|

PickUp Trucks

|

Cars

|

|

|

|

Motorcycles

|

Heavy Trucks

|

|

|

|

Earth Moving Equipment

|

|

We offer unique turnkey solutions that encompass everything from "Concept to Commissioning"

Our turnkey management services have been utilized by reputable Tier 1 suppliers and OEM's that count on us for unique manufacturing solutions. We pride ourselves on being able to develop solutions that meet the budget and quality requirements of our customers.

To meet project quality goals along every step of the process, we review at various stages:

- Design Release

- Release for Dispatch

- Technical System Acceptance

- Verification of Process Capability

- Final Acceptance

Our services include:

- Design & Simulation

- Production / Procurement

- Tryout

- Installation

- Stabilization

- Training

- Documentation

- Planning

We provide complete project management and onsite supervision during Installation and Stabilization.

Turnkey product design, development, simulation and prototyping

Industrial Design

Industrial Design

- Research and Benchmarking

- Concept Design and Development

- Ergonomic Design

- Iterative Modelling

- Styling

- Interactive Design

- Manufacturing Feasibility Assessment

- Digital Mock-up

- Visualization Studies

Product Design and Engineering

Product Design and Engineering

- Assembly Validation

- Detailed Design

- Product Variants

- Design Validation / Support Tolerance Analysis

- Value Engineering

- Cost-Optimization Analysis

- Reverse Engineering

- DFX (Manufacturability, Power, Variability, Cost, Yield or Reliability)

- DFMEA (Failure Mode Effect & Analysis)

- Design Data Migration

Partner expertise of developing EV Programs

- Energy System:

- Li-Ion Battery cell integration of different chemistries

- Battery health monitoring and management.

- Regenerative Braking

- Traction System:

- Single speed low noise high precision Transmission assembly,

- Efficient and powerful induction Motor

- Motor controlling system with many advanced features.

- Power Electronics System:

- Charging Systems and Protection System,

- Fast Charging System.

- Electrical HVAC System:

- Developed very efficient and effective electrical HVAC system.

- Vehicle Information and Monitoring System:

- Vehicle Control unit and fully programmable LCD base Cluster, displaying the Vehicle information.

- Remote Diagnosing and Connected Car system:

- GPRS based Telematics for remote diagnosing and monitoring the vehicle status.

- Mobile App to monitor vehicle condition and control the vehicle.

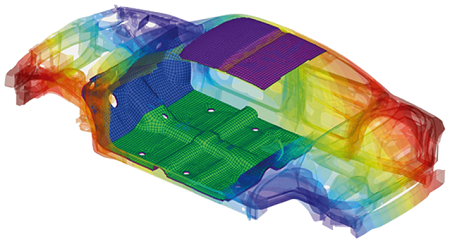

Engineering Analysis and Simulation

Engineering Analysis and Simulation

- Structural Analysis

- Thermal Analysis

- Non-linear Analysis

- Design Optimization

- Computational Fluid Dynamics

- Designing of Experiments

- Flow Analysis

- Failure Analysis

- Fatigue Studies

- Kinematics & Dynamic Simulation

Prototyping

- Reduces Development Time

- Reduces Development Costs

- Requires User Involvement

- Developers Receive Quantifiable User Feedback

- Facilitates System Implementation Since Users Know What to Expect

- Results In Higher User Satisfaction

- Exposes Developers to Potential Future System Enhancements

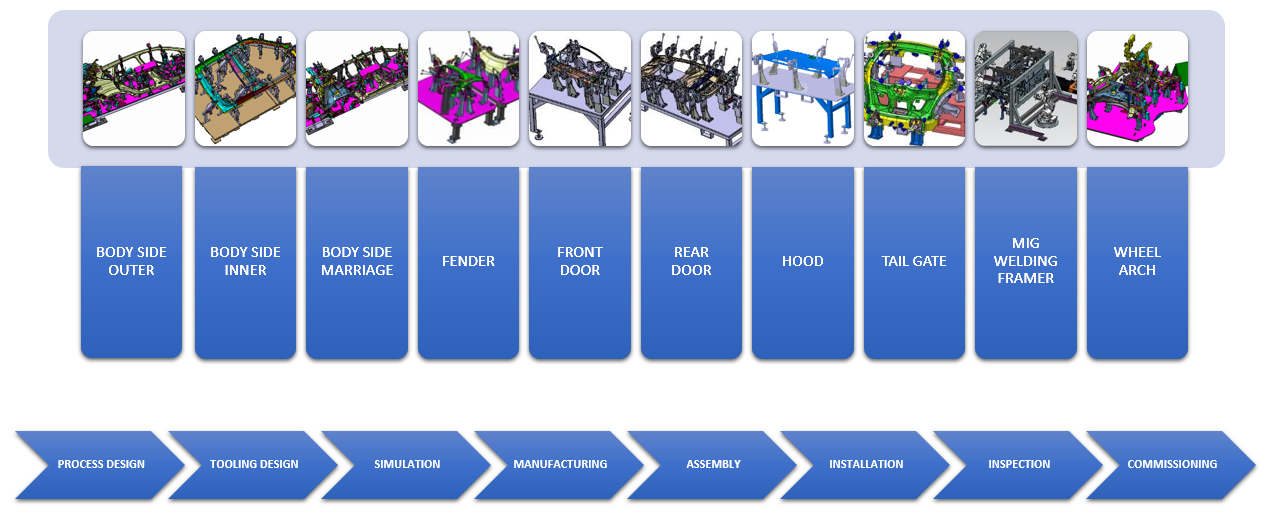

Body Shop Tooling

- Innoac has extensive knowledge in controls hardware and software design that extends throughout the entire body shop. We have experience in designing and commissioning systems for underbody, body sides, framing, closures and respot areas.

- Innoac has an experienced, diverse team of professionals with unparalleled expertise in OEM vehicle body assembly and welding solutions.

- At Innoac we provide a dedicated service package that includes project management, design, manufacturing, commissioning, training and support.

Process and Robotic Simulation

- Validate and Optimize the Process

The simulation team analyzes alternate scenarios to identify a process with optimum cycle times. By simulating robot motions during design, the team verifies whether the robots will be able to achieve the required motions without interference and arrive at a realistic cycle time and throughput.

- Validate and Optimize the Tools

The simulation team validates and ensures that EOAT designs are suitable for all robot tasks and associated equipment. All necessary tooling and robot attachments go through multiple design iterations based on simulation validation of gun access in/out, gripper access in/out, robot payload, robot reachability, tool access, clearance, swept volume, etc.

- Validate and optimize Plant Layout

Layout of systems can significantly impact overall cycle time. The simulation team uses Robotic simulation to determine workcell layouts with optimal placement of peripheral equipment such as fence, floor tracks, light screens, etc. Different factors such as work points, cycle time constraints, reachability and interference are taken into consideration, while designing the layout.

BIW Solutions

Fixtures

General Assembly Tooling

Design, Manufacturing and Supply of:

- Manipulator (Zero Gravity Manipulation)

- Walking Beam Transfer (Lift and Carry)

- Overhead Gantry (Pick and Place)

- EMS Systems (Electrified Monorail System)

- Automated Handling Systems

- Robotic Handling Systems

- Overhead and Floor Mounted Conveyors

- Roller, Power and Free, Slat, Belt Conveyors

- Elevators

- Tool Rails

- Task Systems

- Hand Tools

- Nut Runners

- Test and Audit Areas

General Assembly Solutions

General Assembly Solutions

- Chassis - Elevator, Conveyor

- Seat / Interior / Trim - Conveyor, Manipulator

- Door Assembly - Manipulator Assistance (On/Off)

- Electrical Harness

- Powertrain - Marriage Area

- Urethane and Glass - Dispensers / Manipulators

- Fuel Tank - Manipulator

- Brake Circuit - Installation and Test

- Air Conditioning - Installation and Charging

- Brake / Coolant / Power Steering - Charging

- Wheels and Tire - Manipulator, Nut Runner

- Fuel Pump - Filling

- Spare Tire - Manipulator

- Wheel Alignment

- Head Lamps and Tail Lamps - Manipulator, Aiming

- Roll Test, Brake Test

- Leak Test / Water Test

Gantry, Lifts, and Conveyors

- Pick and Place Gantry

- Lift and Carry System

- Door Handling Conveyor

- Overhead Scissor Lift

- Roller Conveyor

Manipulators, Conveyors, Lifts

- Automated Feeding Machine

- Scissor Lift

- Manipulator

- Power and Free Conveyor

Vehicle Redeployment Makes Sense

- Maximizing Return on Investments by extending life of Vehicle Production.

- A new vehicle program requires tremendous financial, marketing, intellectual and time investments. Deploying these vehicles in a developing and low-cost country not only yields new source of an annuity but also establishes early product loyalty and name recognition. Most developing economies will initially allow imports but will mandate an eventual product localization.

- Once the financial and strategic decision has been made to deploy or transfer production, Innoac can support all aspects of migration to another country.

Transfer / Redeployment Services Offered

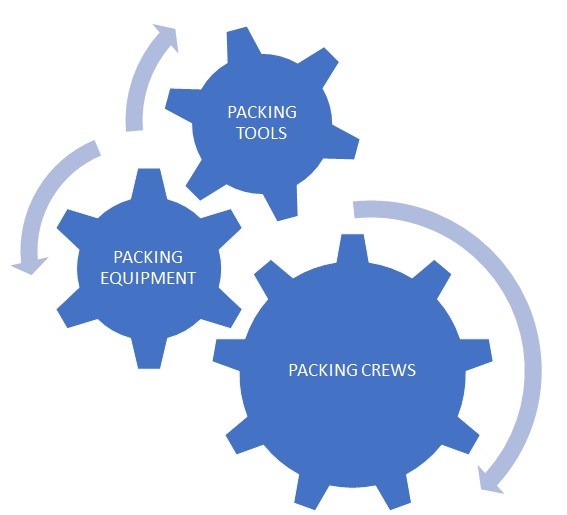

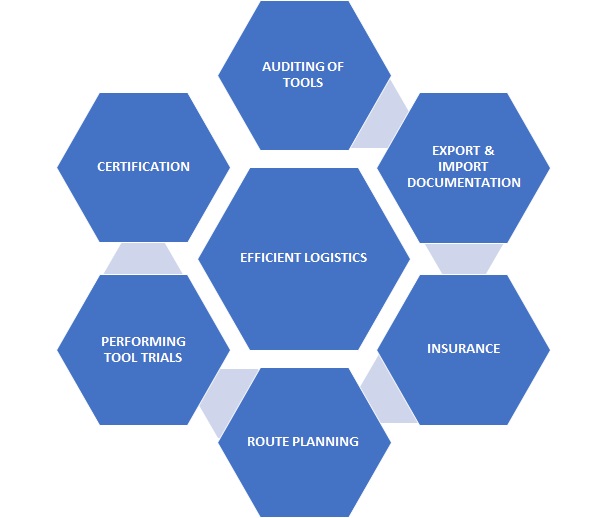

Whether the choice is a CKD implementation with GA migration or Full supplier Chain migration, Innoac has automated and highly organized processes and experienced people capable of handling

- Dismantling GA and Weld lines

- Assessment of Tools

- Tracking and Tagging of Tools

- Product BOM and DMU

- Packaging (Logistics)

- Shipping (Logistics)

- Creating Export Documents

- Customs Clearance

- Create RFQ in the Target country

- Assessing and selecting Suppliers

- Delivering to the Target Suppliers

- Unpacking / Removing Debris

- Installing Tools, GA Lines, Weld Lines

- Reprogramming and Commissioning new Tools / Lines

- Assisting target suppliers with PPAP, etc. to assure OEM Quality

- Reconfigure and optimize the lines for Target Production Rate

- Design and Build new lines to achieve the Target Production Rate

- Provide Training

- Provide post SOP support

- Assist and complete the Target country Homologation

- OEM / Supplier Audit of Process and Tools

Competencies

At the Core - Resources

Expertise

Modes of Transport Offered